STIEBEL ELTRON builds on craftguide as a long-term digital strategy partner

30 percent time and manpower savings: video and 3D step-by-step instructions help skilled workers install equipment such as heat pumps more efficiently, quickly and easily

Broad range of use cases: craftguide can be used at various stages across the value chain to increase efficiency

craftguide, provider of digital instructions for training and further education in trade and industry, was able to win Stiebel Eltron as a long-term customer. The pilot and test phase quickly showed the added value for customers: Compared to the printed instructions, the installation of the devices with the animated 3D and video workflows was more understandable, quicker, error-free and easier. For this purpose, craftguide supplemented the workflows with the original CAD data of the equipment and mapped them as 3D step-by-step instructions on the digital twin. The advantage: once the workflows have been digitally captured, they can be adapted quickly and cost-effectively. Specialist tradesmen and interested customers can access them via a QR code in the installation instructions.

Image source: craftguide

Image source: craftguide

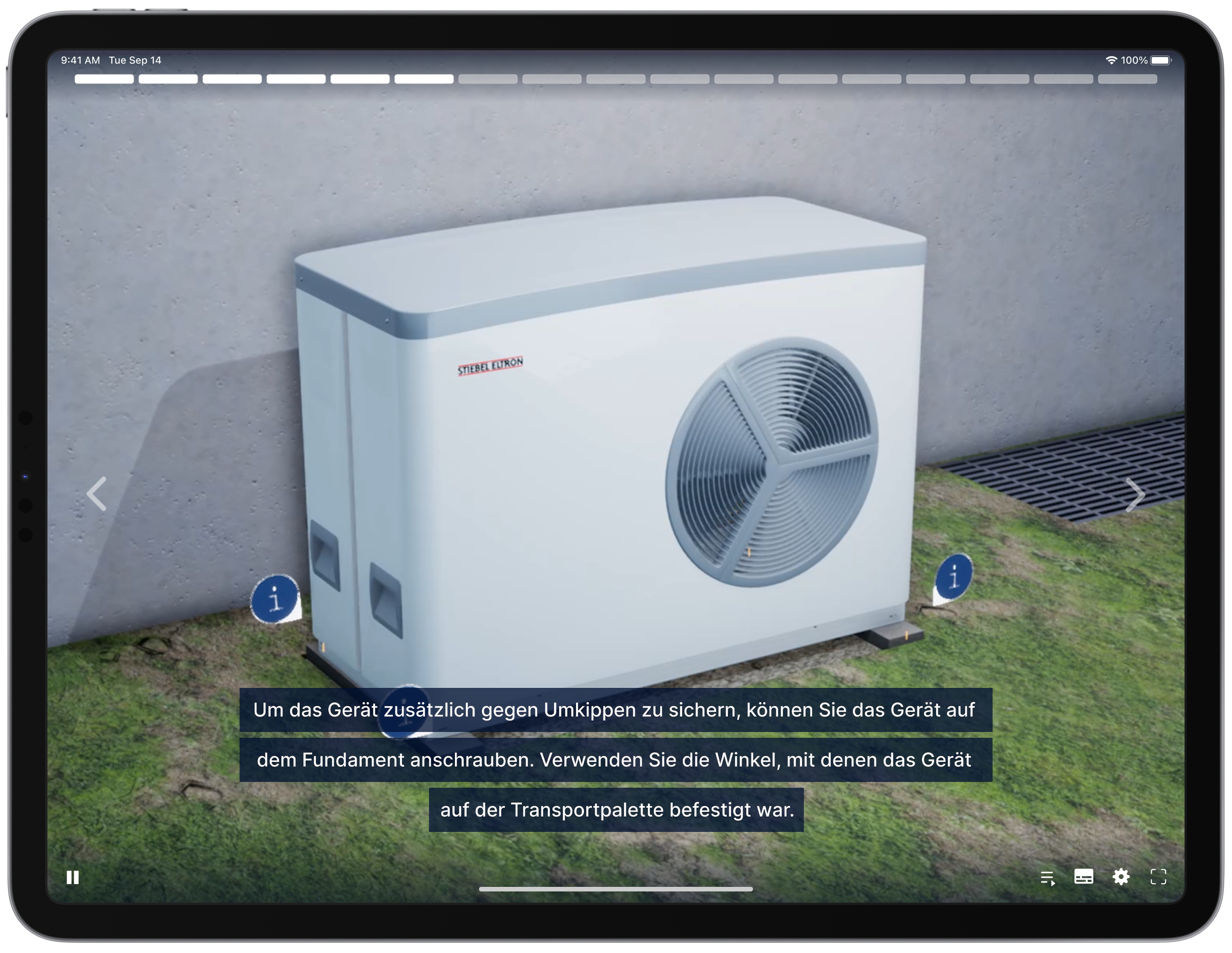

The pilot phase has already resulted in 22 digital instructions for seven devices, most notably the initial setup and installation for the WPL-A 07 heat pump. Customers and skilled workers can access the workflows even offline via the QR code on the package, in the print instructions, or via the craftguide app.

Example heat pump WPL-A 07: the first four workflows

The first four digital instructions from craftguide for the WPL-A 07 HK 230 Premium air-to-water heat pump show in step-by-step 3D video sequences how to prepare the installation site, set up the heat pump, connect it, fill and vent it, and connect it electrically. A playlist automatically leads to the next workflow. Each step is guided by text and digital voice - in 42 languages, if desired. The result is error-free and fast installations without prior training for any type of heat pump. After all, not even the skilled worker is able to know the operation for all heat pumps by memory.

Dominik Golüke - Head of Product Management Building Technology at STIEBEL ELTRON

“As product comparability increases, valuable content around the device makes all the difference - especially when it simplifies our increasingly complex world.”

“In our extensive pilot phase, we experienced craftguide as an open, forward-looking partner that is very close to the customer. The feedback from our test series was implemented immediately.”

"We are very pleased to have now created the contractual framework for a long-term strategic partnership with craftguide.”

Image source: Stiebel Eltron

Multiple purposes: information needs of customers, facilitation in customer service, virtual training material

In the training center and for mobile training purposes, the workflows are accessed using virtual reality glasses: they immerse the user in a simulated reality in which he or she interacts with a virtual machine. This makes it possible to cover workflows for new devices in just a few minutes, taking all safety precautions into account.

Markus Oltmanns - Head of Technical Documentation and Product Information Management at STIEBEL ELTRON

"We expect that skilled workers can save at least a third in time and manpower when installing our heat pumps - which is a huge benefit given the current shortage of skilled workers.”

“Our operating instructions with the linked craftguide video tutorials are available online for each device. The first evaluations show: Technically interested customers inform themselves about our devices in advance via the animated video instructions."

Image source: Stiebel Eltron

International and up-to-date: appealing to different target groups and generations

Manufacturers are required to provide printed instructions. Users can access the digital workflows via QR codes in the printed instructions and on the packaging.

The combination of printed and virtual instructions simultaneously serves the user behavior of different generations. For those who prefer reading, the print instructions remain; for those who prefer videos, Stiebel Eltron provides modern future technologies for knowledge transfer.

The craftguide instructions are also easily localizable and internationally scalable. This is a huge advantage for an international company like Stiebel Eltron: Workflows can be displayed in more than 40 languages using the brand's corporate terminology.

Advantages of craftguide workflows briefly summarized from Stiebel Eltron's point of view:

Fast, error-free, simple and safe installation of the equipment.

Craftsmen save about a third of the time and manpower needed to install a heat pump

Easy access via QR codes on the package and in the print instructions

Information source for customers through public access to workflows

Facilitation in customer support

Training via VR glasses

Internationally scalable: workflows are available in 42 languages

Quickly and easily adaptable in the product lifecycle; also very well suited for other company brands (modular construction kit)

Can also be used for replacing spare parts

Future technology picks up young generation; print instructions serve familiar user behavior

Here you can view the animated 3D video instructions for the WPL-A 07 heat pump. They are also publicly accessible online via the operating instructions at https://www.stiebel-eltron.de/content/dam/ste/cdbassets/current/bedienungs-_u_installationsanleitungen/instructionandinstallationmanual_doc-00073309.pdf Simply click on the QR codes of the step-by-step instructions and you will be taken directly to the workflows.

About STIEBEL ELTRON

Stiebel Eltron, founded in 1924, is one of the leading companies in the market for renewable energies, heating and building technology, with annual sales of over one billion euros.

As an innovation-driven family business, Stiebel Eltron follows a clear line in the production and development of products - for environmentally friendly, efficient and comfortable building technology. With around 5,000 employees worldwide, the company consistently relies on its own know-how from product development to production. The result is efficient and innovative solutions for hot water, heating, ventilation and cooling. Stiebel Eltron manufactures at its main site in Holzminden in Lower Saxony, in Hameln (NDS), in Freudenberg (NRW) and in Eschwege (Hesse), as well as at four other sites abroad (Arvika/Sweden, Tianjin/China, Ayuttaya/Thailand, Poprad/Slovakia).

Further information: www.stiebel-eltron.com